This year, amotIQ is once again supporting the school fruit project at the ev. Martin Luther Kindergarten in Heilbronn. Every week, the children receive a delivery of delicious, seasonal fruit from regional suppliers, which is available to them as a healthy addition to their meals. This gives children a taste for healthy foods that are rich in vitamins and fiber, and they learn to integrate them into their daily eating routine at an early age. Through the specialists at the facility, the children also learn more about their origins and a conscious and mindful approach to food. We are happy to contribute to this.

Our employees are important to us – which is why we were able to obtain the “Employer of the Future” seal in 2023, which focuses on digitalization and sustainability. Our employees work in a future-oriented company and, due to the digitalized world of work, can optimally combine work and free time – of course, we also want to appeal to young and experienced, highly qualified employees.

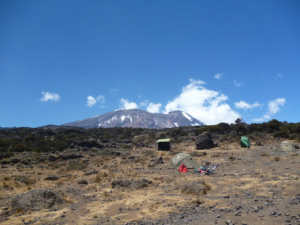

What do our managing directors and consultants do to keep fit for our customers and projects?

Under the following link we present the “little hobby” of amotIQ solutions managing director Michael Schulz. He offers outdoor, trekking and hiking activities at home and abroad as well as tips, tricks and packing lists for all interested people. More info can be found at:

Success obliges!

A successful year comes to an end and we welcome the new year with confidence.

We wish you a good and easier, successful and healthy 2022.

We see our success as an obligation to let others share in it.

At the end of the year we are very happy to support the Heilbronner Tafel, the Mitternachtsmission and Pfiffigunde in Heilbronn.

Good news at the end of the year: amotIQ automotive starts the new year with two new colleagues:

Petra Engelke will support the Vibracoustic Support Team as of January 1. The experienced colleague will relieve her colleagues Wolfgang Gust and Volker Spachmann.

On January 1, 2022, our new colleague Marleen Kaiser will also start working for amotIQ IQaRS.

With Petra Engelke and Marleen Kaiser the amotIQ team grows to 37 employees – always on duty for all amotIQ customers.

We wish both new amotIQers a good start and much success at amotIQ automotive.

With giant steps we are approaching Christmas. We have celebrated St. Nicholas, open a new door of our Advent calendar every day, the lights in our Advent wreath are burning, the houses are decorated for Christmas, the last projects in the old year are successfully completed. Soon they will be here, the very special, festive days, also this year.

We say THANK YOU for the good and trustful cooperation, and we wish our customers, partners and employees with their families a wonderful pre-Christmas time, a Merry Christmas and a good start into the New Year.

But most of all good health. And don’t forget: Your amotIQs are always there for you, even between the holidays…..

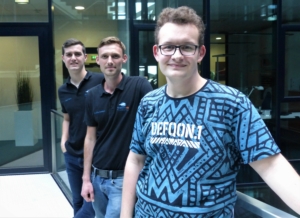

Our former students are now Bachelor of Science (B.Sc.)

We are proud of all our colleagues – and even more so if we were able to accompany them during their training. Following Albert Renz, who successfully completed his studies at Heilbronn University in April, our two DHBW students Yannick Haas and Robin Dörschuck have now also completed their Bachelor’s studies. All three colleagues now hold the title of Bachelor of Science (B.Sc.) and are permanent employees at amotIQ automotive.

A career at amotIQ can happen very quickly if you are committed and qualified. Our former working student Albert Renz has been in charge of tool development at the company since October. Since April he is employed as IT-Consultant & Developer. He received his promotion after only half a year, just in time for his 24th birthday. This makes him currently the youngest employee in the company – and already in a management position.

Yannick Haas has been a permanent employee at amotIQ automotive since October: “I had already signed my employment contract in my 4th semester and had been looking forward to this day ever since. Actually, a master’s degree was also planned, but I realize more and more that I enjoy the practice much more than the theory. The study contents are more or less outdated compared to what we do with amotIQ IQaRS.”

Robin Dörschuck has also been a permanent member of the amotIQ team since October. His bachelor thesis will support the work of amotIQ and its customers: “It is planned to provide an abbreviated version of my bachelor thesis to the colleagues at the customer so that they can better understand the forecasting method used so far. The work will provide a basis for future adjustments and changes to the forecasting method.”

We wish all three colleagues all the best and a continued successful cooperation in the amotIQ team.

The school fruit project at the Ev. Martin Luther Kindergarten in Heilbronn has also been a success with the children. With a sweet picture, the little ones say thank you for fresh fruit every day at lunch in the kindergarten.

amotIQ knows: financial means are available for kindergartens and schools only for the most necessary purchases due to lack of funds and subsidies.

Special requirements and wishes have to be cancelled due to lack of resources and funds. We are happy to sponsor this beautiful campaign and thereby help to ensure that children are regularly supplied with fruit and vegetables and that the little ones are re-introduced to a healthy diet.

Children suffer more and more often from overweight; healthy nutrition can partly no longer be ensured at home due to low wages and lack of time of parents.

We want to contribute to changing this situation. This project is intended to show children how delicious healthy food can be.

We are happy for the little ones!

The Martin Luther Kindergarten in Heilbronn and Future Sport were looking for supporters and amotIQ automotive is happy to support this good project. Future Sport: “Without such socially committed entrepreneurs like you, additional special projects at kindergartens and schools would hardly be possible.”

Unfortunately, due to a lack of funds and grants, financial resources for kindergartens and schools are only available for the most necessary purchases, which is why special requirements and wishes are cancelled due to a lack of resources and funds. Thanks to a sponsorship, children can be regularly provided with fruit and vegetables – a project that aims to re-introduce children to healthy eating. Children are increasingly suffering from obesity, and healthy food can sometimes no longer be provided at home due to low wages and a lack of time on the part of parents.

When it comes to the well-being of children in the region, amotIQ automotive is happy to sponsor good projects!

Megatech Industries has carried out the annual evaluation of its service companies with the title Service supplier evaluation – MEGATECH Industries Waldbröl 2020.

In it, amotIQ automotive achieved a score of 92 and, with this super value, continues to be one of the A service providers of the long-standing customer Megatech.

In particular, the 10 out of 10 possible points for the quality of work, good communication, flexibility, fair prices and reliability of amotIQ pleases everyone involved. It is nice that Megatech recognizes what we have known for a long time: For our customers we want to be the best and most reliable at the fairest conditions! Always fast. Always flexible. Always amot.

Megatech Industries is an international automotive supplier specialized in plastic components with headquarters in Vaduz, Liechtenstein.

Megatech Industries was founded in 2009 by Maximilian Gessler and is an automotive supplier and partner in the development and production of systems, modules and plastic components for passenger cars and commercial vehicles. The product range includes center consoles, door panels, interior and exterior pillar trim, load sills and floors, headliners, seat backrests, wheel arch trim and technical components.

Contact

amotIQ automotive GmbH

Lise-Meitner-Straße 6

74074 Heilbronn Germany

Telefon: 07131-587707-0

Telefax: 07131-587707-20

info@amotiq.de

About AmotIQ

amotIQ automotive GmbH was founded on 21st December 1999. The three automotive Managing Directors and founders of the company are Peter Heidecke, Frank Mysliwitz and Andreas Prescher. Part of the team were also eight other shareholders – all of them visionaries and very down-to-earth. Located in the heart of the German automotive region, the internationally operating company specializes in consulting and development services for the automotive industry.

News

Social commitment at amotIQ4. July 2023

Social commitment at amotIQ4. July 2023This year, amotIQ is once again supporting the school fruit project at the ev. Martin Luther Kindergarten in Heilbronn. Every week, the children receive a delivery of delicious, seasonal fruit from regional suppliers, which is available to them as a healthy addition to their meals. This gives children a taste for healthy foods that are […]